Well, if this were easy then everyone would be doing it. Or so the saying goes. There are occasions when we question whether we should be doing it. And then we keep going.

D1PPS

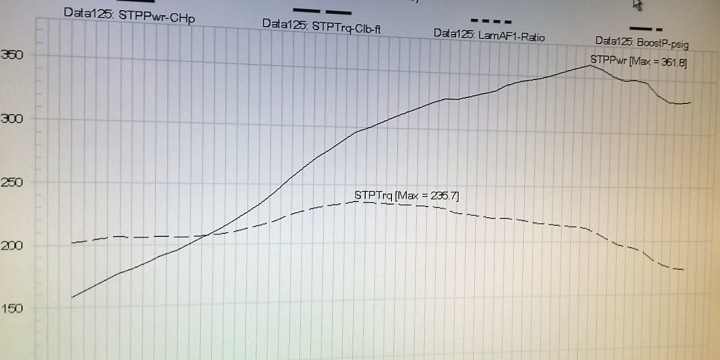

In order to have the car ready for shakedown on the 31st, in preparation for the June 4-5 testing, we have to have the engine done now. Actually yesterday would have been just fine. Or two weeks ago. Fortunately, George is making good progress. He’s now going through boost levels. 277 hp at 8 psi. 361 hp at 10 psi. It’s a three hour drive to Seattle so I set out around 6:30 pm to miss the traffic, with the goal of picking up the engine and driving right back. Things are looking up.

Around 8:30 pm I get a call – the header cracked. We knew that we would need support for the turbo in the actual car, but gambled on having it dangle off the header for dyno testing. Bad bet. George is able to MIG weld it, but of course it takes time. So when I get there around 10 pm with construction traffic, he still needs to do a few pulls. The welded header looks decent enough and Tristan can beatify it some when we get it back. The old flywheel is there as a reminder that things can go wrong.

Watching dyno runs is always exciting and stressful at the same time. Yes, of course the engine will do exactly this countless times in the car, but somehow being strapped on to a test rig it looks more uncertain. With good reason, I suppose, because this is still development.

We do a couple easy pulls to get it warmed up. The intercooler water flow is turned off to help the engine get warm quicker. Then we’re ready for 14 psi run (16 psi is the planned maximum). All is looking good. The engine spins up, power keeps rising past 330 at 7K RPM… and then drops. George shuts it down. There are no bad noises or smoke, but something clearly is not right. DAMN. We didn’t turn on the intercooler water. Engine turns over but doesn’t start. It is now 11 pm, after several days of working crazy hours to get things done. Not looking good. A compression check confirms we have a problem – cylinder 1 is good but 2-3 have only 40 psi and 4 has zero.

We pull the head and cylinder block – OUCH. Portions of the head melted away between the exhaust valves and got smeared on cylinder walls and pistons.

We’re going to need a new head, cylinder block and a set of pistons. There is a head back at the shop in Portland. Several cylinder blocks at George’s shop. Pistons are the unknown. By midnight we’ve done all we can, a plan is formulated and I set out on a 3-hour drive home. Not exactly what I had hoped for.

Next morning up at 8 – lots to do. George makes many phone calls looking for pistons while we pack up the head and get it on its way. There are no pistons in stock anywhere, nationwide. It’s not looking good. I do always have contingencies. This one requires asking for favors, but this is where we are. We need to get Rodney familiar with how the car behaves. Fortunately there is a car that is almost exactly like the D1PPS – the D1 that Neil owns, and it’s here in town. I had tentatively inquired with Neil earlier as to whether we could ‘borrow’ the D1 if need be. Well, need be. Neil comes through and we pick up the D1 – tomorrow we go to ORP.

In the meantime, work continues. Lots of pieces are coming together. The ‘ideal’, or rather best-case, scenario at this point would be us getting the rebuilt engine Monday, having the rest of the car ready to ‘just plug it in’ (yeah, right), then shaking it down Tuesday at ORP and taking it to Colorado on Thursday. Worst case, otherwise known as realistic, Tristan will stay in Portland to work on the D1PPS while we go to Colorado with the D2RS only and have Jonathan and Rodney share test runs.

Last thing in the day George finds some pistons and they’re on the way. We’ll see what happens next.

D2RS

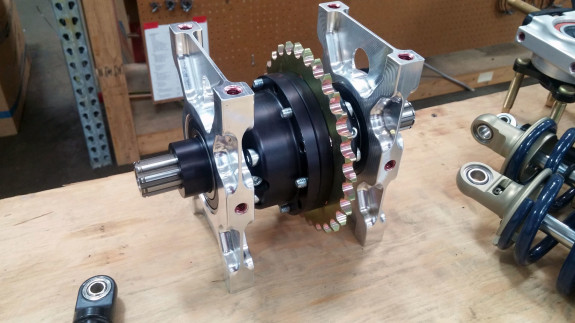

Dramatic as the D1PPS developments may be, it isn’t the only car we have to get ready. So somewhere in all this we have to keep making progress on the D2 as well. And we do. The nose liner prototype part is now done. Fortunately this week we have one of our summer interns, Chris, start his work. We made him jump right in and he’s been doing great so far. Today’s task – trimming the nose liner part and starting to fit it with the chassis and the rest of the panels.

It’s getting there but lots more work to do. No rest for the wicked.