There is a reason Pikes Peak International Hillclimb is celebrating its 100th anniversary this year – it’s a magical place, and despite (because of?) all the challenges the Mountain throws at competitors, it’s addictive. We want to come back. Also, we’ve learned a lot from the past efforts and want to try some new things. Yes, plugging in the boost controller is one of them 🙂

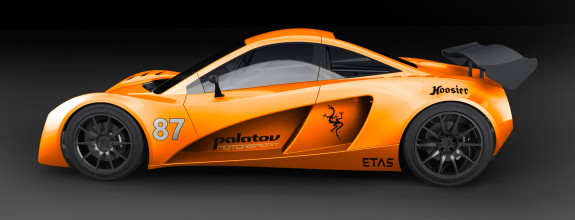

As you probably already know, we’re running two cars. Both are derivatives of earlier designs and both have significant modifications. Since it’s basically two separate race efforts that just happen to be part of the same team, each blog post will have two sections – one for the D1PPS and one for the D2RS. As of today, this is what the two cars look like.

Yes, the D1PPS is just a chassis at this point although we have a lot of the parts for it. We have less than a month to put it together and get it running. The D2RS is a drivable car but all the old bodywork is going to come off and will be replaced with new design. This is what the cars will look like when done, approximately.

Now on to the details.

D1PPS

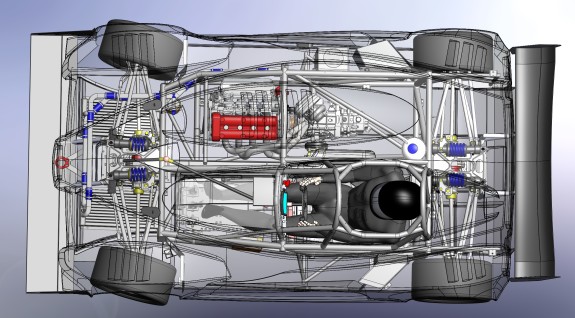

One of the major changes from the 2012 car is the 4-cylinder turbo engine. The layout will look like this.

We had a Hartley H2 engine onhand, in fact it was the very first one in existence – we were the development customer for it. I knew that John had evolved his designs quite a bit so the decision was made to send it back for upgrades. The list is long but the key parts are listed below.

The major one is a billet crank with larger bearings and a 72mm stroke (vs 63mm originally). This results in a 1.5L displacement, up from original 1.3L. Along with it come custom connecting rods (to work with larger bearings), remachined and line bored case, and spacer plate. Also adjustable cam sprockets, longer timing chains, and so on.

The outside of the engine also got separate sprockets for oil pump and alternator drive.

The final significant upgrade is a very compact custom water-air intercooler.

The engine is now completed and on its way to us. Once it arrives, we will fit the exhaust that Tristan has already welded up of 321 stainless, along with a turbo and some plumbing. It will then go on the dyno for tuning. We’ll be shooting for up to 400 hp.

There is a lot of machining and fabrication taking place. I’m also running a lot of CFD in SolidWorks for aerodynamic improvements, but all of that will be reported on in later posts.

D2RS

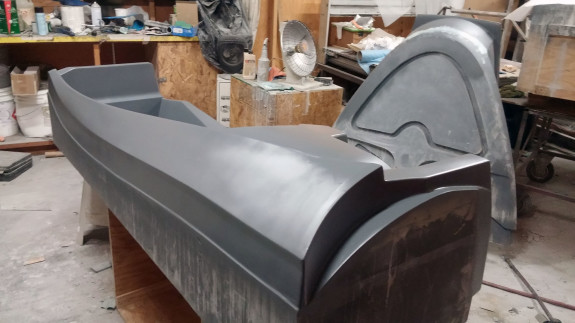

Since the chassis and running gear are mostly carried over from last year, the focus of this year’s D2RS development is on the bodywork. Willamette Pattern has been hard at work machining the patterns and then making molds. The nose, tail and door skin molds are now fully done. Side panels are in progress while we finish work on the nose ‘liner’ pattern and then the canopy.

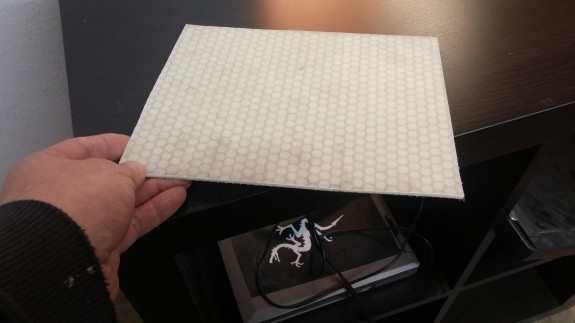

M&W Fiberglass is doing the actual layup of parts. Yesterday Mike brought by a sample of the layup we’re going to use – it’s a resin-infusion molded fiberglass with a high tech core material. Ends up being 30% lighter than regular layup, and has high stiffness and strength, with about 0.1″ thickness. A 12″x9″ panel only weighs 10 ounces and can support Tristan’s weight without breaking.

Really looking forward to the first finished parts!

As before, the schedule is tight, as is the budget. We have a huge amount of work ahead especially considering that the Pikes Peak cars are not the only projects we’re working on, and we still haven’t fully unpacked from our recent move. There is a lot of uncertainty and numerous challenges which we need to overcome, in order to face the ultimate one – the race itself.