This is actually two posts in one. The reason for this is that it’s just been crazy dealing with everything we have had to do since Thursday’s test, and there just hasn’t been time to do a blog update.

First, the test. When we arrived and unloaded at ORP, things looked promising. We had sorted the leaking clutch circuit the night before and everything appeared to be ready. Also, Neil brought out his D1 and Roman came out to drive his D2 after some maintenance.

Jonathan took the race car out for some initial laps but came in after just a couple. Problem with the clutch – it seems like it doesn’t want to engage and is always slipping. After some calls, we learned that the carbon clutch needs to be broken in and should get better after a few heat cycles. Unfortunately, further attempts to run resulted in it getting progressively worse, to the point where the car couldn’t even be driven into the trailer at the end and we had to push it in. Not a good start but there was nothing more we could do with it here.

On the upside, the little track time that Jonathan did get in the car led him to conclude that the chassis is very confidence inspiring and that he’ll be comfortable relying on it up on the Mountain. This is a critical part of the equation so it is good to have that answer.

We never do just one thing at a time and this day was no exception. We brought our faithful demo D2 (now 60+ trackdays) as a backup to let Jonathan get more seat time in the chassis, and some old and new friends came out to experiment with video and generally have fun on track.

One of the things we want to do is share our adventures. There are countless ways to do that, this blog being one, and video is another. There are lots of new technologies – drones, gimbals, high-res cameras – but we are focused on the cars and don’t have the bandwidth to mess with it ourselves right now. So when someone comes along willing to put their own effort and resources into experimenting, we jump at the opportunity.

Today Arvid Elias (a Seattle-based car and video enthusiast) brought his drone, gimbal setup and camera to see how the video might turn out. Click on the picture below for a compilation of drone footage. Since all the sound that the drone gets is the whine of its own rotors, I used a royalty-free music clip that we purchased a little bit ago. Turned out pretty fun I think and we’ll look into getting our own drone down the line.

The reason this is fo the future is that we won’t be able to use a drone at Pikes Peak and our focus is on the race right now. With that in mind, we also tried a gimbal-mounted camera setup on the car. Here’s the result. I think it shows promise although further experimentation with location, field of view and sound is in order.

The rest of the day was used to get Jonathan more seat time in the demo D2, give demo rides and get more video and pix. All in all a good test day even though all didn’t go smoothly.

You’ll notice the D1 in the drone video – Neil was out with his car and making great progress. Jonathan now really has to work the demo D2 to try and keep up with him and it’s gratifying to see.

Getting back to the shop at 8pm, Tristan took the floor off the race car and peeked into the bellhousing with a flashlight. It looks like the release bearing is pressed hard against the clutch spring. This explains why the clutch is not engaging. There isn’t a lot of wear material inside the bellhousing so there is reason to be optimistic that this can be sorted.

An added challenge is that tomorrow is Friday and the weekend makes it difficult to place rush orders for parts and supplies. But we’re ready to scramble.

Friday the transmission comes out and we remove a 1/4″ spacer under the bearing that was installed to set the air gap to about 0.1″ originally. It seems the clutch spring has extended significantly in the first few minutes of use. In one of the phone calls from the track we were told this does happen, but it seems a bit excessive.

Still, the clutch seems OK so we put it together and reinstall the transmission. Still not enough space. So out it comes again and after writing a quick CNC program and machining down the bearing mount another 1/4″, everything now fits and the airgap is around 0.2″ just to be safe.

We test the pedal travel and clutch engagement, and both seem reasonable. But next week we leave for Colorado to run the first tests on the Mountain on the 6th and 7th. We need to verify that the car is working before we drive 25 hours each way.

Fortunately, Tristan has been talking to Jason Oefelein at Portland Speed Industries, a local tuning company that has a dyno and a lot of experience. They are enthusiastic about our effort and are willing to open up on Sunday to put the race car on their dyno. It’s an opportunity to both test the clutch under full power in controlled conditions and get some basic tuning done.

Right away Jason impressed me with both the extent of his knowledge and his approach – he starts with identifying the car’s intended mission and then comes up with a tuning strategy that’s specific to what we’re trying to do. In this case, ultimate power is not necessarily the goal but reliability and predictable power delivery is. Jason understands the challenges of altitude and knows the LSA engine well.

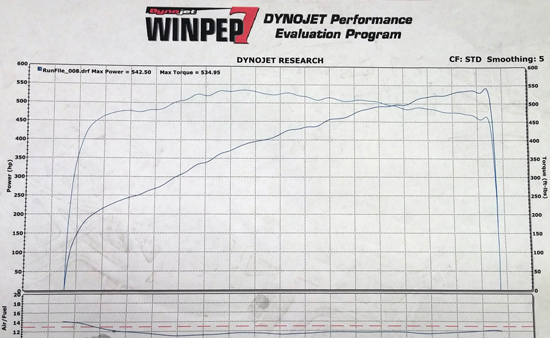

We strap the car in and an initial pull with everything still cold produces a little over 560hp at the wheels (that makes it roughly 660hp at the crank). Not bad on standard pump gas, with catalysts on 🙂 Click on the picture below for a short video clip.

We are running in 50-state emissions legal form for several reasons. One is just my personal belief that if racing can be made more environmentally responsible while still delivering the performance, we should take every opportunity to do so. The other reason is that we want to show what a customer D2 can do – this is a car anyone can buy and drive on the road, every day.

Jason explains that as the temps go up the power will drop slightly and that he is going to tune parameters like ignition timing, MAF scaling and fuel delivery to make the engine efficient, and also to provide a safety margin in the extreme environment of Pikes Peak. The final result is below – 542hp at the wheels with everything hot and 535 lb-ft torque. In a 1,900 lb car that’ll do.

Crazy few days and there’s still a bunch of stuff we need to do to the car but it’s all manageable now. We are basically ready to test. Current weather at the summit – below freezing and snow. This will be an interesting experience. Jonathan is flying out a day early to drive the road in a rentacar and see what he’s really up against.