Since we are running with the old bodywork, it’s time to fit it and send it off for paint. Which is what we did, adding some extra ducting for the intercooler.

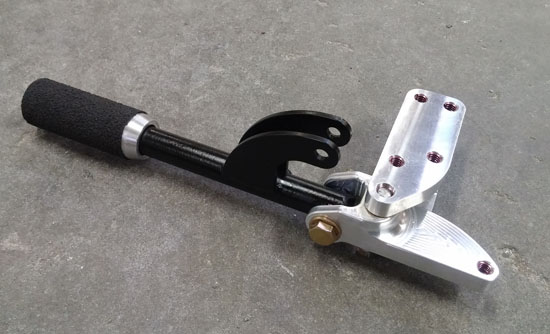

There is a list of various things we need to tweak. The main one is the alternator/waterpump belt setup. After talking to manufacturers of electric water pumps we’ve determined that we have to stay with the mechanical one for our application. To improve reliability we are switching to a manual tensioner and using a laser alignment tool to make sure all the pulleys are precisely in plane. Hopefully this will take care of the issue. Other bits include things like an improved shifter setup, changes to headrest and minor things like that.

Many have mentioned that our car might be too quiet for Pikes Peak – the spectators need to hear it coming. Electrics are forced to use an annoying siren for that. Just to make sure we don’t end up having to do the same thing, we built and tested a set of pipes without the mufflers. The catalysts are still on for 50-state emissions compliance. The car sounds cool! – here’s a quick video clip.

On the subject of videos, I went through our footage from the testing and put together a composite clip as well as three different camera views for upper and lower section runs. Links below.